When it comes to the construction and mining industries, an aggregate crushing production line plays a vital role in transforming raw materials into usable aggregates. This system is designed to efficiently crush and process various types of materials, including granite, limestone, basalt, and recycled concrete, into gravel, sand, and other aggregates. The production line typically consists of several stages, including feeding, crushing, screening, and washing, each of which is crucial for ensuring high-quality output.

The initial stage of an aggregate crushing production line involves the feeding of raw materials into the system. This is typically done using a vibrating feeder, which evenly distributes the material to the primary crusher. The primary crusher, usually a jaw crusher or gyratory crusher, is responsible for reducing the size of the large stones into smaller, more manageable pieces. This process is essential for preparing the material for subsequent crushing stages and ensures that the overall efficiency of the production line is maximized.

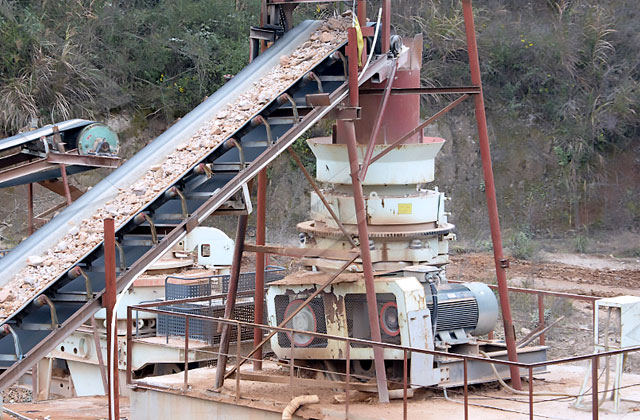

Following the primary crushing stage, the material is usually transferred to secondary crushers, which can include cone crushers or impact crushers. These machines further reduce the size of the aggregate and shape it into the desired form. Cone crushers are particularly effective for producing high-quality aggregates with a consistent shape, while impact crushers are known for their ability to produce finer materials. The choice of secondary crusher depends on the specific requirements of the project and the characteristics of the raw materials being processed.

After the crushing stages, the aggregates are screened to separate them into different size fractions. This is typically done using vibrating screens that sort the material based on size. The screened aggregates can then be washed to remove any impurities, such as dust or clay, ensuring that the final product meets industry standards. This washing process is crucial for applications such as concrete production, where the quality of the aggregates directly impacts the strength and durability of the final product.

Investing in an aggregate crushing production line can be highly beneficial for companies looking to enhance their production capabilities. With the right equipment and setup, businesses can achieve high production rates while maintaining the quality of their aggregates. Moreover, many manufacturers offer customizable solutions tailored to meet specific operational needs, ensuring that the production line can efficiently handle various materials and production volumes. Overall, a well-designed aggregate crushing production line not only boosts productivity but also contributes to cost savings and improved profitability for businesses in the industry.